Sludge Removing Kit 3 in 1

Sludge Removing Kit 3 in 1

Mã sản phẩm: 8511

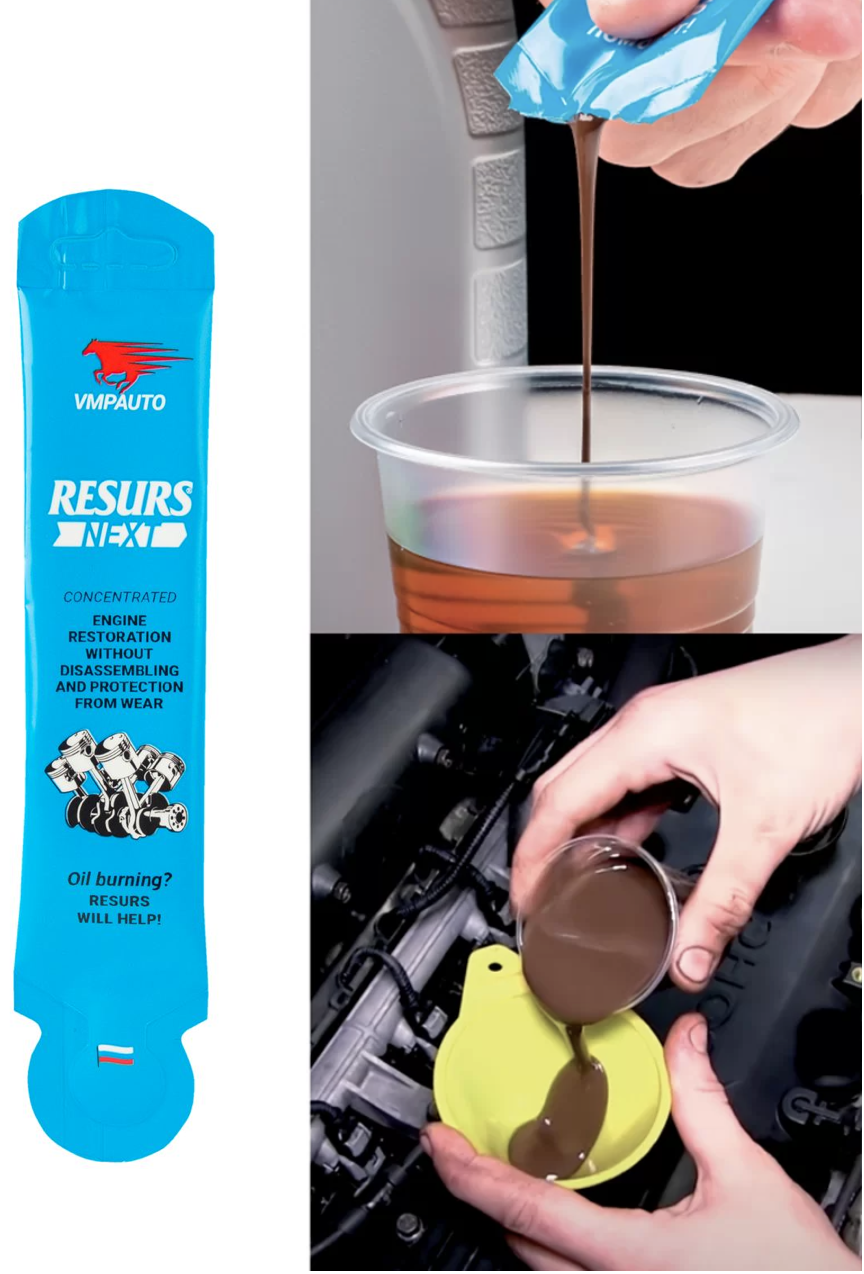

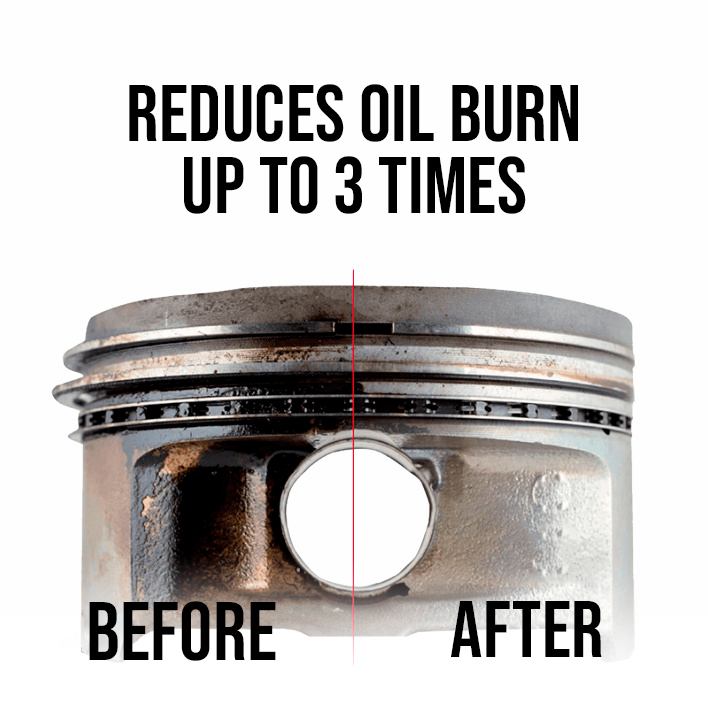

One set for complex engine decarbonization from sludge. Effectively cleans the combustion chamber, valves, compression, and oil scraper rings. After cleaning, protects the friction surfaces from further wear. The complex use of decarbonizing foam, decarboil and remetalizing additive increase the efficiency of the cleaning procedure.

Bao bì: -

Mã sản phẩm: 8511

Decarbonization is the process of removing hard-to-dissolve deposits: high-temperature varnish, resins, carbon deposits, which are resistant to traditional flushing.

Unlike liquid decorbanizer, RESURS foam carbon cleaner fills the entire volume of the combustion chamber, cleans nozzles and valves. With five dissolving and rinsing cycles, it works more effectively.

This name belongs to an amazing product, which is applied as simply as flushing, and works in strength like Decarbonizing.

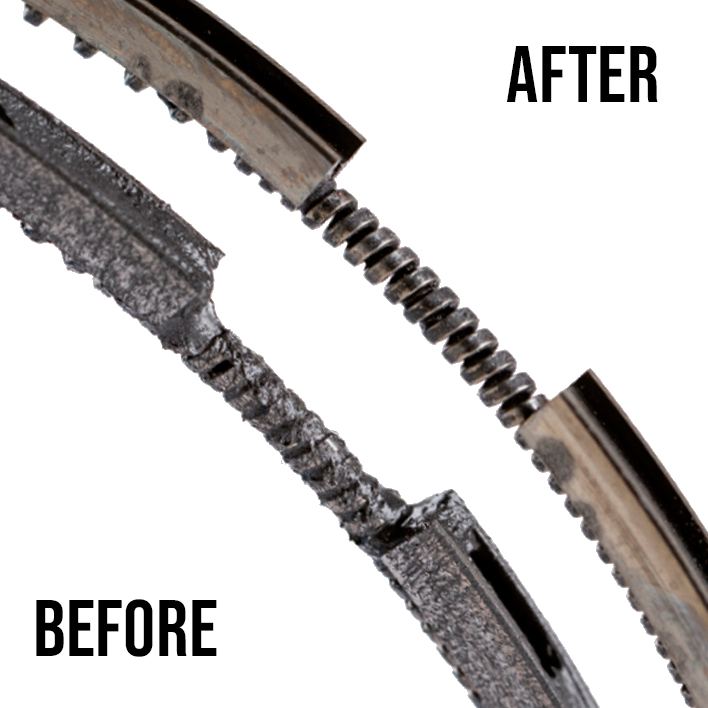

Decarboil opens the drainage holes of the piston and restores the mobility of the oil scraper rings

To make the engine clean, as from the factory, it is necessary to repeat the procedure 2-3 times.

Attention: Do not leave RESURS Decarboil with used oil in the engine. After applying Decarboil, it is necessary to drain off the used oil and refill fresh oil. Otherwise, it is possible for the engine parts to stick together due to the high concentration of dissolved resins in the used oil.

Due to its high efficiency, price and compactness, it has conquered the population in various parts of the world: Nigeria, Mexico and Russia.

After the carbon deposits have been removed, it is necessary to protect the cleaned engine surfaces with metal nanoparticles. The particles use oil as a means of delivery to the friction zones, where, under the influence of temperature and pressure, they block at the micro levels, being embedded in the crystal lattice.