Surface preparation

Thoroughly clean and degrease the surfaces to be coated with Thinner 646 or C2-80 / 120 nefras. After surface preparation, it is not allowed to get on the parts of water, oil and other contaminants. The gap between the preparation operation and the application of the MC2000 composition should not exceed 60 minutes. Do not touch the degreased surfaces of parts with unprotected hands.

Application.

The composition of MC2000 is applied in 1 ÷ 2 layers

The composition of MC2000 is applied in 1 ÷ 2 layers. The recommended thickness of the cured composition is from 7 to 15 microns. The second layer is applied after drying the previous one in the air at room temperature until matt appears (30-60 minutes)

Stir MC 2000 thoroughly before use with a clean stick or stirrer for at least 10 minutes. At the end of mixing, the composition should be a uniformly black liquid, while no sediment should remain on the bottom and on the walls of the bottle. If necessary, it is possible to dilute MS 2000 with solvent 646 or technical isopropyl alcohol.

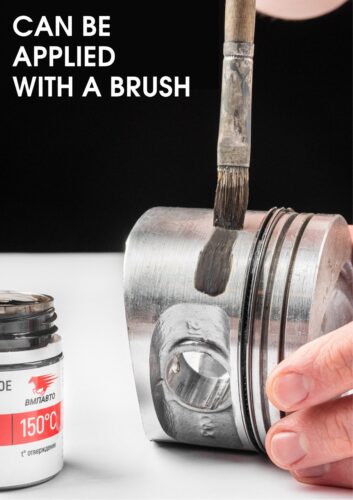

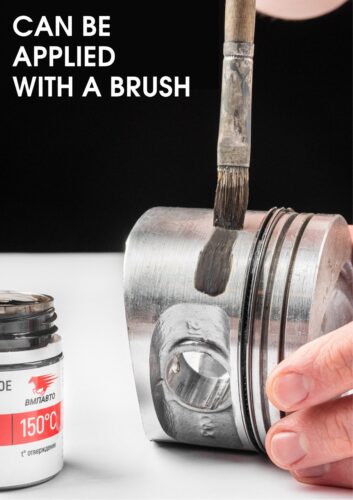

Apply the composition at room temperature using one of the following methods: spraying, dipping, stencil or brush 3. Surfaces should be coated as evenly as possible.

Curing.

The coated parts are dried in air for 60 minutes, then heated in an oven or oven to plus (150 ± 10) ° C at a rate of (1-3) ° C per minute, and then kept at this temperature for 1 .5 -2.0 hours. Cooling to 70 ° C is carried out in an oven, then in air at room temperature.

Quality control.

By visual inspection, the coating should be matt, solid and black. Bubbles, delamination, foreign inclusions, craters, glossiness, mechanical damage are not allowed. The degree of curing of the coating is controlled by the rinse test, which is as follows. Using a cotton swab moistened with solvent 646, rub the same hot area 10-15 times by hand with slight effort. Satisfactory curing does not wash off the coating, but the color of the cotton swab may turn gray.

Notes.

The durability of the coating depends on the surface roughness, the optimal value of which is Rz = 1.6-3.2 microns. Preliminary sandblasting and chemical surface treatment are recommended.

It is advisable to control the thickness of the cured coating with a thickness gauge for paints and varnishes. If the thickness of the coating is greater than the required one, it is allowed to fine-tune the specified thickness by lapping with the mating part. Abrasive cleaning is prohibited.

Most preferred is spray application allowing control of coating thickness, maximum adhesion, and wear resistance. The use of the stencil method of application is recommended for serial production.